The National Automotive Design and Development Council has called for an end to the importation of vehicle tyres and batteries into Nigeria, saying the move is critical to strengthening local manufacturing, boosting Gross Domestic Product, and deepening the country’s automotive value chain.

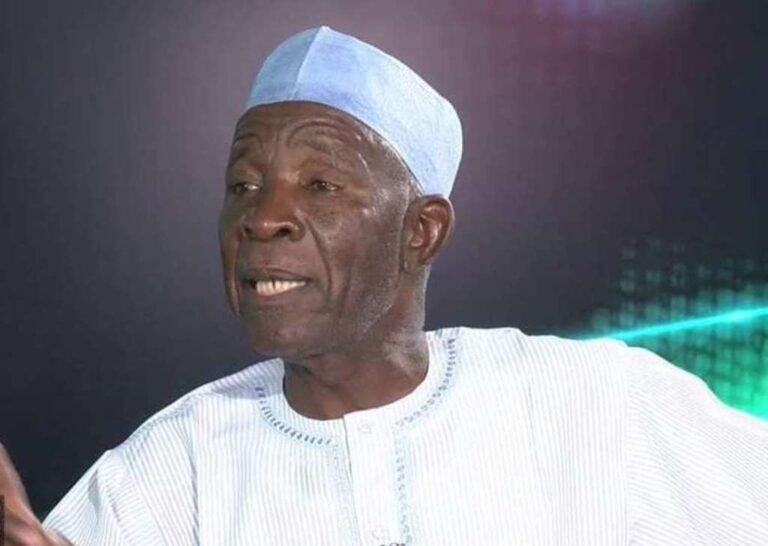

The Director-General of NADDC, Oluwemimo Joseph Osanipin, made the call on Thursday in Abuja at a one-day sensitisation workshop for stakeholders in the tyre and battery industries.

The workshop, themed “Revitalising the Automotive Value Chain in Nigeria: Strategies for Growth in the Tyre and Battery Sectors,” brought together regulators, manufacturers, financial institutions, and industry groups.

Osanipin said Nigeria spent over N1tn on tyre imports in 2024 alone, describing the figure as unsustainable for an economy seeking industrial growth and foreign exchange conservation.

“We are committed to a future where the vehicles on our roads are not only assembled here but are also built with local components manufactured by Nigerian hands. This workshop is designed to sensitise manufacturers and investors on the vast opportunities available in the domestic production of tyres and batteries, ensuring that we reduce our over-reliance on imports and strengthen our domestic value chains.

“According to our survey, Nigeria spent more than one trillion naira importing tyres last year. This is why we are advocating an end to tyre and battery importation and encouraging local manufacturing to grow GDP and fast-track national economic development,” he said.

The NADDC boss explained that the workshop was designed to build on outcomes of the 2018 National Tyre Conference, which identified the urgent need to revive the tyre and battery sub-sectors amid persistent challenges.

He noted that the industries currently face constraints around raw material sourcing, product certification, quality assurance, and mandatory end-of-life recycling.

Osanipin said the forum also focused on strengthening local content implementation under the Nigeria Automotive Industry Development Plan (NAIDP-2023), particularly through backward integration in tyre production as well as lead-acid and lithium-ion battery manufacturing.

“We are no longer just discussing assembly; we are focusing on the core building blocks of the industry: Tyre Production: Promoting the local sourcing of rubber, synthetic rubber, and carbon black. Battery Manufacturing: Encouraging the production of lead-acid and lithium-ion battery plates right here in Nigeria. Quality Assurance: We are working closely with the Standards Organisation of Nigeria to ensure that every “Made in Nigeria” component meets stringent safety and performance protocols.

“The workshop provides a comprehensive platform to discuss backward integration strategies, quality and compliance, and to educate stakeholders on evolving standards such as tyre age limits and battery performance requirements,” he said.

According to him, discussions also covered New Energy Vehicle technology, including the safe handling, charging, and management of high-voltage lithium-ion batteries, as Nigeria prepares for the gradual electrification of its transport sector.

He added that sustainability featured prominently, with clarity provided on the End-of-Life Vehicle framework, especially on the responsible collection and recycling of waste tyres and batteries.

Osanipin said the sensitisation exercise also created a direct regulatory dialogue, allowing manufacturers and importers to engage authorities on industry-specific challenges and bottlenecks.

Reaffirming NADDC’s commitment to promoting made-in-Nigeria products, Osanipin expressed optimism that the initiative would support President Bola Tinubu’s Nigeria First Policy, which prioritises local production and consumption.

In a goodwill message, the Director-General of the Standards Organisation of Nigeria, Dr Ifeanyi Okeke, described tyres as a safety-critical product and warned that substandard imports posed serious risks to lives.

Okeke, who was represented by Pankes Clement, Assistant Director and Group Head, Chemical Technology, said SON would continue to collaborate with NADDC to enforce standards in local tyre manufacturing.

“The tyre is a life-threatening product if it fails. That is why standards must not be compromised,” he said.

Also speaking, the Chairman of the Nigeria Automotive Manufacturers Association, Bawo Omagbitse, called for deliberate efforts to create a sustainable tyre market in Nigeria, noting that local production would deliver significant economic benefits.

He said ending tyre and battery imports would strengthen local content and accelerate the growth of Nigeria’s automotive industry.

Similarly, the Chairman of the Motorcycle Association of Nigeria, Rev Lambert Ekewuba, urged NADDC to sustain stakeholder engagement and awareness campaigns to boost patronage of locally manufactured automotive products.

He pledged the association’s support for policies aimed at developing Nigeria’s automotive ecosystem.

The workshop featured technical presentations from officials of the Federal Road Safety Corps and other stakeholders, alongside goodwill messages from representatives of the Bank of Industry, NEXIM Bank, and other key partners.

Nigeria currently imports the bulk of its tyres and batteries despite having a large domestic market and a growing vehicle population, a situation industry players say presents a major opportunity for industrialisation if properly harnessed.

The push to localise tyre and battery production comes amid renewed efforts by the Federal Government to revive the automotive industry following years of decline caused by import dependence, policy inconsistency, and foreign exchange pressures.

The Nigeria Automotive Industry Development Plan was first introduced in 2013 to encourage local vehicle assembly and component manufacturing through tariff differentials and fiscal incentives. However, weak enforcement, high production costs, and smuggling limited its impact, forcing many assemblers and component makers to scale down operations.

With the government also preparing for a gradual transition to cleaner transport options, including compressed natural gas and electric vehicles, policymakers say developing local capacity in tyre and battery manufacturing is critical to sustaining the automotive ecosystem and reducing long-term import exposure.